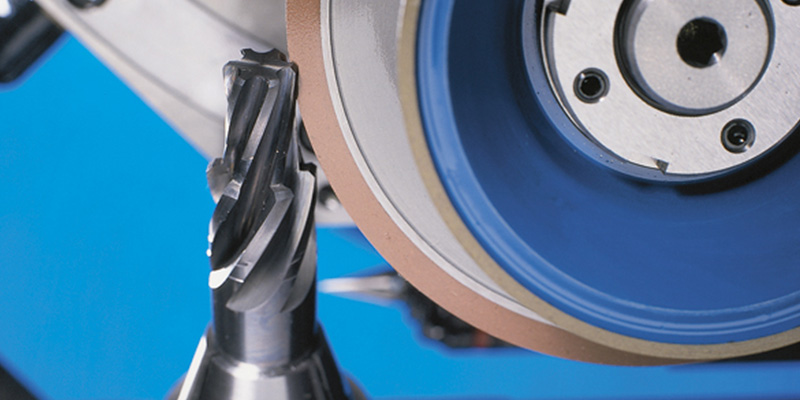

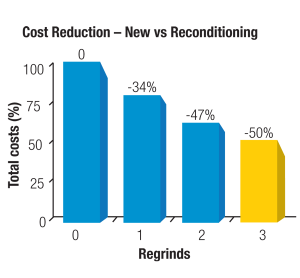

The regrinding service significantly reduces tooling costs over buying new tools. Our customers benefit from Sutton Tools advanced super abrasive grinding expertise providing high accuracy and quality. All tools are subject to stringent quality and performance checking and testing to ensure best results.

Regrinding services available:

- Regrinding of carbide and HSS standard products

- Refurbishment of diamond tools

- Manufacture of solid carbide threaded products

Why choose Sutton Tools regrinding services:

- Regrinding services returns tools ‘as new’ condition

- CNC grinding machines are operated by experienced personnel

- Helps reduce tooling costs over buying new tools

- Using state of the art CNC tool and cutter grinders and drag finishing machines

Surface Technology Coatings Service

Complementing our regrind facility, Surface Technology Coatings (a division of Sutton Tools) provides a physical vapour deposition (PVD) coating service, and is at the forefront of heat treatment and surface engineering technology.

In addition to providing PVD coating, STC provides plasma nitriding and vacuum heat treatment for various tools and components. Our unique position enables us to provide tailored solutions to a wide range of friction and wear problems.

Services available:

- PVD Coatings

- Stripping Service

- Vacuum Heat Treatment

- NitroPlas Plasma Nitriding

- Steam Oxide Treatment

Contact your local representative for further details.