Digital strategies behind the ‘Smart Enough’ Factory

There’s a lot of talk about Industry 4.0 and Smart Factories. Dr Steve Dowey, Technology Manager at Sutton Tools, explains our approach and why becoming a ‘Smart Enough’ Factory can be a more feasible solution for all-but-the-largest manufacturers.

Many manufacturers with a large burden of legacy systems – and especially smaller-sized organisations – see the vision of the Smart Factory as too complicated, and therefore unachievable in the short- to medium-term. The German Platform Industrie 4.0 initiative is admirable and, in April 2017, our Prime Minister’s Industry 4.0 Taskforce entered into a cooperative agreement for information sharing between our two countries, including the development of global Industry 4.0 standards – with the Advanced Manufacturing Growth Centre coordinating work in Australia.

But many German companies are large sized – in terms of revenues and people – and therefore have the turnover/economies of scale to justify complex new digital manufacturing strategies, at least on new process lines.

As an Australian manufacturer ourselves, although with a global customer base, we see many of the customers we work with running smaller operations. For example, OECD data shows that around 90% of Australian manufacturers have less than 20 staff.

This led us to consider how smaller businesses can effectively adopt an understandable and scalable digital strategy, without taking a whole-of-business approach. Our solution is the Smart Enough Factory – a model we’re following ourselves.

The Digital Triangle strategy framework

The Digital Triangle strategy framework

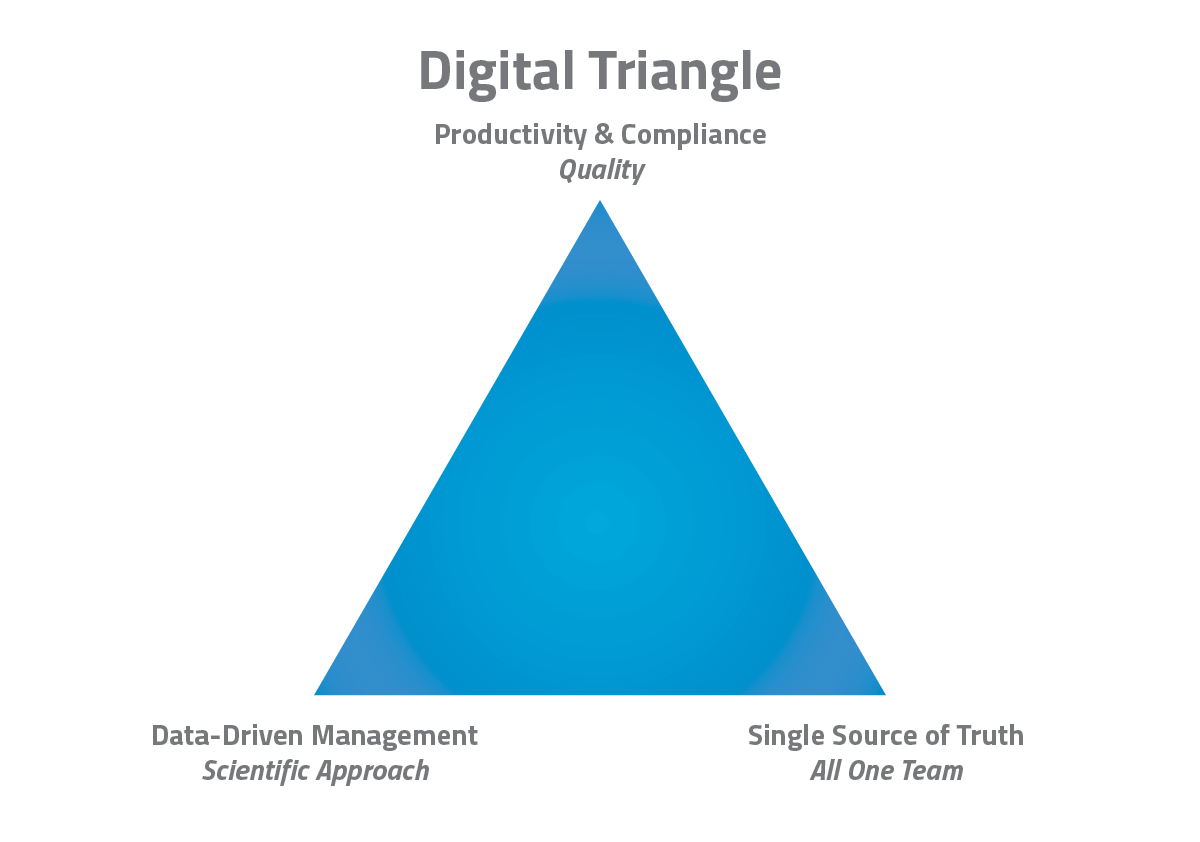

Many will be aware of The Joiner Triangle, introduced by Dr Brian Joiner – who was a student of influential US engineer Dr W. Edwards Deming – as a framework for implementing quality improvement. The Joiner Triangle of Quality/Scientific Approach/All One Team, which was adopted by Ford, and can be considered in the same light as the Fire Triangle of heat/oxygen/fuel: if one is lacking, the fire goes out!

We’ve built on that to create a Digital Triangle as a strategy framework for creating the concept of a ‘Smart Enough’ Factory:

We also referenced Lean Manufacturing principles in building our Digital Triangle – and that makes it as relevant to smaller organisations as global behemoths. The Lean Manufacturing discussion focusses on the application of the strategy. Lean principles include elimination of waste.

We also referenced Lean Manufacturing principles in building our Digital Triangle – and that makes it as relevant to smaller organisations as global behemoths. The Lean Manufacturing discussion focusses on the application of the strategy. Lean principles include elimination of waste.

What is ‘Smart Enough’?

The Digital Triangle strategy is an alternative model to the Reference Architectural Model Industrie 4.0 (RAMI 4.0) model. I took ‘Smart Enough’ from the concept that ‘Good enough is Good Enough’. It’s an enabling philosophy developed for SMEs to get into Industry 4.0, in that it looks for practical factory solutions based on low-cost technologies.

The biggest concerns expressed about Industry 4.0 manufacturing are based around its cost, security and the skills required. Smart Enough doesn’t fix any of these roadblocks, but it does bypass them by deploying:

- Rapid Application Development (RAD) tools, typically low code – to address the skills issue

- Low-cost edge devices and sensors linked to a wireless network and deployed locally (not in the cloud) to mitigate latency and security issues

We also deliberately focus on management data and not traditional control applications. In a Smart Enough Industry 4.0 deployment the control loop is closed by the operator or manager and not the system, mitigating the security issues that closed loop control introduces.

Whether your processes are using CNC systems or not, you can still overlay a wireless sensor network to gather the data you need from your machines in order to gain transparency and immediacy of process information (one of the goals of IoT). When a machine state changes the event triggers a wireless message.

Whether your processes are using CNC systems or not, you can still overlay a wireless sensor network to gather the data you need from your machines in order to gain transparency and immediacy of process information (one of the goals of IoT). When a machine state changes the event triggers a wireless message.

Combined, this offers even small operations a reliable factory visualisation tool. Simple, basic data can greatly enhance management control and productivity. You can monitor utilisation against your targets, predict whether you’ll make them then see what you need to do if you won’t.

A lightweight overlay, collecting only the management data you need to control your manufacturing operations, is a cost-effective Industry 4.0 digital strategy towards that even small-scale manufacturers can deploy.

My next articles will look deeper into increasing manufacturing productivity and compliance through digital strategies and provide some practical examples.

Please contact us if you’d like to discuss our Smart Enough Factory approach – or any other manufacturing or tooling questions we could help you solve.