Harmony 5-Axis endmills take the curves

Jeff Boyd introduces an endmill range which is central to an exciting new initiative with Swinburne.

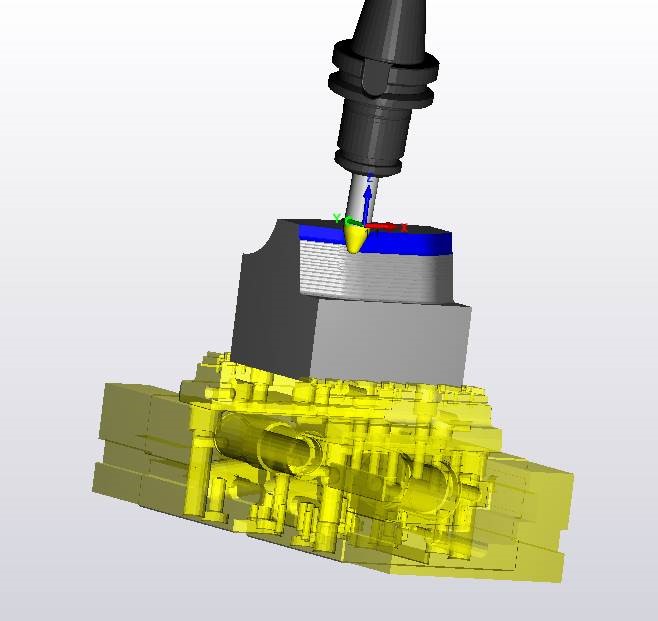

We recently participated in the Haas Melbourne Performance Week, demonstrating the capabilities of the new HAAS UMC750 5-Axis model, among others. For us, the stars of the show were our new Harmony 5-Axis endmills. Available with barrel, taper, lens and oval configurations, they have the ability to reduce cycle times by up to 90%, compared with ball nose endmills.

Put to the test

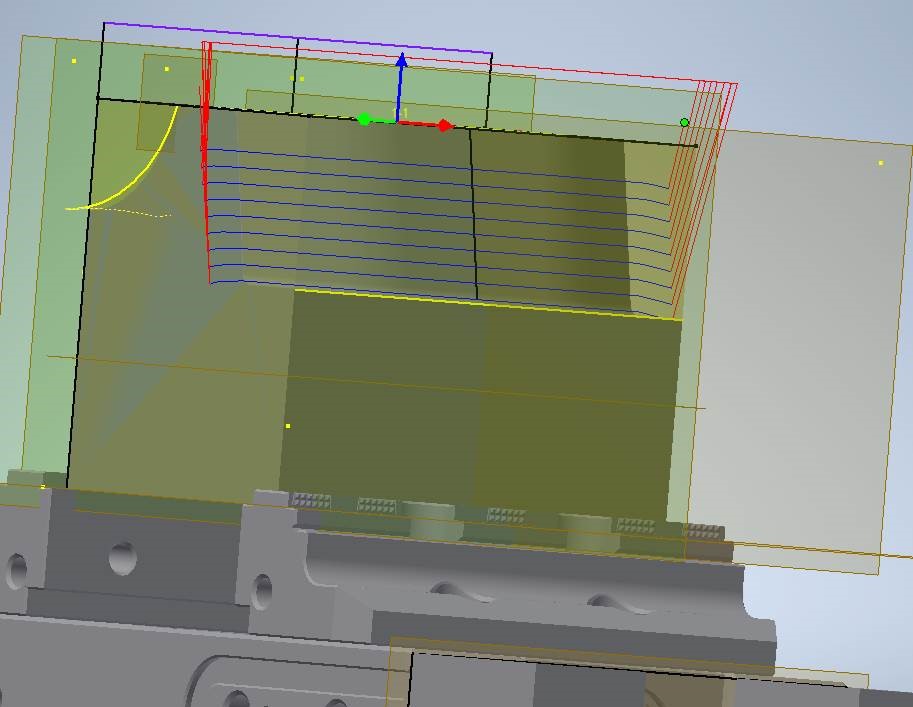

We set up a demonstration that pitched a 1500mm radius Harmony 5-Axis taper form endmill against a traditional 8mm radius ball nose endmill. Both set to work on finishing a curved tapered wall surface at a cutting speed of 200 m/min and a 0.11mm feed per tooth.

The goal is to match the scallop height (surface roughness), using either of the tools and compare the time taken to machine the same surface area.

The difference was that the Harmony 5-Axis endmill is able to achieve a 4mm step over, compared to a 0.3mm step over with the ball nose. It took just under 2 minutes, compared to 10 minutes with the ball nose. Giving them a full work-out we set them up finishing a tapered wall similar to that of the internal cavity of a deep pocket mould.

And it’s not only this level of performance & time saving that’s a benefit, but also the precision of the tool’s profile. With less 10µm profile deviation, this offers very high workpiece accuracy, making it ideal for finishing operations of high-tech 3D printed components in the additive manufacturing space of aerospace & medical industries.

Also, for the subtractive manufacturing industries, like Mold & Die, the finish copy-milling operation has a huge benefit on cycle time over traditional ball-nose endmill options.

But there’s more!

During the recent Haas Melbourne Performance Week, many of the manufacturing executives and engineers who saw these results were certainly impressed – and it started many conversations about the possibility of customising these endmills for specific applications, a service we are happy to offer.

However, several also remarked that the Harmony 5-Axis endmills, significantly reduced the machines movements. This in turn reduces wear and tear, and hence maintenance costs of the machine. So, the cost benefits of the range come not only from shorter cycle times, but potentially a reduction in the machine’s overhead.

With Swinburne into the future

The opportunities for Australian manufacturers offered by 5-Axis machining play a central role in a new 5-year research agreement we’ve just signed with Swinburne University of Technology. Together, we’re establishing a Smart Manufacturing Centre which will provide training to students, staff and industry in general in addition to ongoing research and development activities.

Under the agreement, Sutton Tools will sponsor three PhD internships at our Thomastown headquarters, as well as taking under- and post-graduate students as part of Swinburne’s Work Integrated Learning Program. Swinburne will loan a 5-Axis machine to Sutton Tools as part of the arrangement.

It’s the latest in an ongoing series of collaboration initiatives between our company and Swinburne, beginning back in the early 1990s. It also fits well with the Australian Government’s Modern Manufacturing Strategy – which is seeking to develop and nurture a digital and sustainable local supply chain. But more about that particular goal in my next blog!

If you’d like to know more about our Harmony 5-Axis endmill series, download our latest flyer, or talk to your Account Manager today.